Talking to a Chinese friend recently, I learned of why electronic water ionizers in Japan are giving way to the newer non-water separating H2 water filter systems. He exports H2 systems into Japan and is amazed at how fast the industry there is evolving.

He told me that the biggest water ionizer company in Japan fell afoul of the government last year.. to the point of being sued by them.

I had visited the company in question, Nihon Trim on my last research trip. They account for 65% of all ionizers sold in Japan. (Enagic is around 5% according to the last official industry report I read).

Nihon Trim make a great water ionizer and really – in my opinion – care for their customers better than any other company I’ve come across.

When it became obvious that the hydrogen content of water was the real therapeutic element, not the pH, things changed fast. And the company, I assume, decided, like us, that this was the way of the future. The ‘Holy Grail’ of ionized water.

The difficulty they faced was the conversion of their marketing approach from alkaline water to hydrogen water. It’s a difficulty I see many vendors experiencing.

Many readers in the industry may think this conversion of marketing would be simple, but not in Japan, where everything is carefully monitored for honesty and integrity.

So my friend’s story ran like this: (and for obvious reasons, I emphasize that I didn’t personally talk to the companies involved).

….. I think Nihon Trim decided that all they needed to do to do capitalise on the new market was to take their present models and begin selling them as hydrogen rich water systems. And that’s when things started going seriously wrong.

In Japan they do it right. If an industry group forms, and is willing to create safety guidelines, the government will enforce them. So when the Hydrogen Water Promotion Association (or a similar name) researched the burgeoning product range and applied the science, they came up with the figure of .8 ppm H2 as a minimum acceptable H2 level in water from a device for it to be sold legally as a beneficial H2 infusion device.”

“The company” he said, “could only respond within the limits of the technology.”

No.. this is important, and it’s something we at AlkaWay have been talking about for over a year.

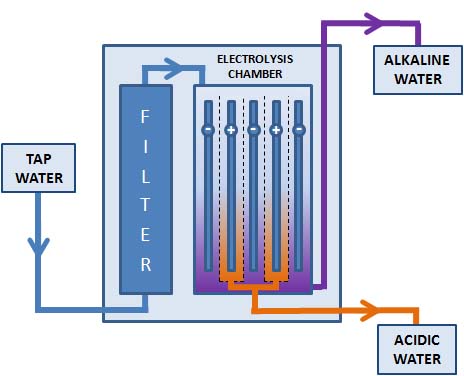

Electronic water ionizers were never designed for H2 production. The basic design is electrolysis, and the design brief was always to create high pH water – not high H2.

To increase H2 levels in an electrolysis system, there’s only one way. You have to increase the voltage of the electricity passing through the water in the chamber. And when you do this, your pH rises.

We’ve stressed again and again.. one shouldn’t have to have this sort of water just to get an acceptable level of molecular hydrogen infused in your water.

The Plate Accretion Problem

The Plate Accretion Problem

One is the fact that the standard of filtration on most if not all electronic water ionizers is basic, so some particulate gets past the filter into the electrolysis chamber where it is attracted to the plates in the chamber. As soon as this deposition

There are two more factors at play. occurs, the ability to get good H2 levels falls away.

Many, many users have mistakenly believed or been told that ORP and pH indicates the level of ‘good’ high H2 water. But recent tests and research have shown this really isn’t so.

Unless you perform a 20-minute acid water cleanse very often, your plates may have accreted particulate, thus inhibiting H2 production. We’ve observed that it takes as little as 14 days to take a new machine to a basically useless H2 generator.

The Bubble Story

The Bubble Story

Secondly, we have seen over the years many water ionizer companies advertising pics of glasses of water full of bubbles. They would usually claim this showed high pH or something like the now debunked ‘microclustering’. It was, we now know, hydrogen bubbles trying to leave! An unsubstantiated observation I’ve heard now from industry peers is that the bubbles are caused because of the agitation at the surface of the electrolysis plates. Now.. we actually don’t want bubbles. We want the H2 to infuse, and our innovation, the UltraStream, delivering high H2 levels, has no bubbles, indicating that the infusion process is a less turbulent one than in electrolysis systems, and therefore capable of delivering the H2 more effectively.

The most obvious conclusion we can come to is that electrolysis – the splitting of water into two ‘alkaline’ and ‘acid’ streams, is a basically flawed method of producing H2 infusion. Remember, the original models, right up to this new H2 revolution, were never designed for H2 production.

So what happened?

According to my source, a supplier of H2 systems in Japan, the government sued Nihon Trim. The case was around the fact that the government in Japan insists on a set safe pH level – above which no system may go. The Nihon Trim company, it appears, could not reach the .8 ppm necessary to be approved as an H2-generating device without increasing the pH of the water above the government’s safety limit.

I don’t know the result of the court case.

What I do know is that the government’s action has affected every Japanese maker of electrolysis-based water ionizers.

The basic design limitation I talked about puts them, in my opinion, between a rock and a hard place indeed.

What It Means

And what does this mean to water ionizer buyers and potential buyers in all other countries where the relative newness of the technology to each country has allowed vendors to basically say or claim whatever could be believed by a customer?

This, I believe, will change, but frankly, I can see no way for the vendors to accommodate the Japan model without completely ditching the electrolysis split water system.

I do appreciate that vendors and manufacturers didn’t willingly create the problem.

It was the advance in our understanding of molecular hydrogen delivery that caused the paradigm shift. We sold electrolysis systems for twelve years and had no idea that it was the H2 causing the amazing stories users related back to us.

And I also appreciate that we scored the ‘long straw’ when we chose to pursue a natural alternative, moving away from the electrolysis method. And.. the longest of the long straws was that when we tested our UltraStream’s H2 delivery against the biggest-selling electrolysis system in the world, the UltraStream delivered almost 4 times the H2 of the far more expensive electronic unit. Remember, the Japanese government says to be designated at a viable H2 system, it must deliver .8ppm H2 infused in the output water. The electrolysis system tested at .3ppm. The UltraStream tested at 1.1ppm.

I would be thinking very carefully before making the major monetary investment in any unit that can’t provide valid independent H2 tests.

If they don’t have them, and they are a big company, there has to be a reason, doesn’t there?

Very interesting thank you. How do you think companies who bottle molecular hydrogen enriched water for the retail market, produce their water? Surely not via ionization?

I would assume by conditioning the water and bubbling the hydrogen in directly and packaging the correct way (sealed aluminium?)

Both

Dispute your assertion that there is only one way to increase h2 supply from electrolysis,by increasing voltage.One can increase plate size,can increase electrolyte concentration.Also,if you use distilled water,instead of just filtered water,you will increase the life of your electrolyte,meaning more like closer to 100 hours between cleansing.Also quality,and type of electrolyte and plates used.By vastly improving method of infusion,I question your claim of not achieving 0.8 ppm hydrogen.Please correct me where I might be wrong,as I,m very interested in this technology,thankyou.

Thanks geoff!

you are right.. and wrong.. What we’ve observed is that electrolysis systems lose H2 ability very fast if the unit isn’t given a 20m clean every 2 weeks. That’s a lotta maintenance. further, electrolysis won’t work on ‘pure’ distilled water.

Hey Geoff, I see you know your stuff. To take your points one at a time:

1. One can increase plate size,can increase electrolyte concentration

Technically yes, practically no. No electrolysis machine has the ability to increase plate size. You’re stuck with what you buy.

2. One can increase electrolyte concentration.

Again, yes, but you’re stuck with the electrolytes coming from your tap. i know some water ionizer vendors suggest adding a a pre-filter to increase electrolytes.. but it’s a messy installation for your kitchen.

3. If you use distilled water with electrolysis it simply won’t work. It needs minerals in the water.

4. Quality,and type of electrolyte and plates used. Certainly one or two water ionizer manufacturers have been working on plate quality to increase performance. however, all electrolysis systems still have the problem of inadequate prefiltration, causing accretion of sediment on the plates. This accretion won’t be noticed if you are measuring pH and ORP, but it will drastically reduce H2 generation. Users of this for of ionizer have found that they have to perform bi-weekly 20 minute cleanses, wasting many gallons of water.

Thanks for bringing up these points!

Ian